Request a Quote

Interested in more info and want to contact us?

Receive a FREE consultation within just 1 business day! We will answer all your questions and provide information on what you need!

-

Defect Detection: High-res lenses for particles, scratches, and pattern flaws

-

Dimensional Accuracy: Telecentric optics for line width and overlay measurement

-

Surface Profiling: Beam combiners for thickness and topography analysis

-

AOI Systems: Vision optics for real-time alignment and defect checks

-

Spectral Tools: Optics for ellipsometry, Raman, and PL testing

-

Cleanroom Assemblies: Vibration-stable, contamination-controlled systems

-

Subsurface Mapping: Optics for fast, non-destructive laser and X-ray scans

-

DUV & EUV Lenses: High-transmission optics for 193 nm and 13.5 nm lithography

-

Projection Systems: Catadioptric assemblies for sub-micron pattern transfer

-

Mask Illumination: Uniform beam shaping for consistent wafer exposure

-

Exposure Control: Optics for precise dose delivery and CD accuracy

-

Anti-Reflective Coatings: Thin films to reduce standing waves and enhance fidelity

-

Cleanroom Materials: UV-grade fused silica and CaF₂ for durability

-

Stable Mounts: Vibration-resistant, thermally stable opto-mechanics

-

Overlay Alignment: Optical sensors for multi-layer registration

-

Raman: Maps stress, strain, doping, and crystal quality via laser excitation

-

PL (Photoluminescence): Reveals bandgap, defects, and exciton behavior through emission analysis

-

Ellipsometry: Measures thin-film thickness, refractive index, and uniformity with polarized light

-

OES (Optical Emission): Monitors plasma processes in etching, deposition, and chamber cleaning

-

UV-Vis & IR: Characterizes absorption, transmission, and reflectance across layers

-

CL (Cathodoluminescence): Detects crystal defects and electronic transitions via electron excitation

-

Quantum Analysis:

-

Thin-Film Metrology: Ellipsometry and reflectometry for angstrom-level film and index measurements

-

Surface Uniformity: Interferometry detects flatness, roughness, and refractive index shifts

-

Defect Inspection: AOI optics identify particles, scratches, and pattern flaws in real time

-

Tool Calibration: Standards verify inspection accuracy and contamination control

-

Scatterometry (OCD): Measures nanoscale features beyond image-based techniques

-

Spectroscopic Testing: Raman and PL optics assess crystal quality and strain

-

Inline Monitoring: Optical sensors track excursions and optimize yield during production

RMI Products Designed For You

Opto-Mechanical Assemblies

Opto-mechanical imaging optics are engineered to deliver high-resolution visuals across UV, visible, and infrared (IR) wavelengths. Designed for demanding environments in medical diagnostics, aerospace surveillance, scientific instrumentation, and industrial inspection, our assemblies ensure sharp, reliable performance with optimized alignment and thermal stability.

Ultraviolet Optics

Ultraviolet optics are engineered for demanding environments in medical diagnostics, semiconductor photolithography, and scientific spectroscopy. Designed for optimal transmission and durability across the UV and Deep UV spectrum, our components deliver accurate, repeatable results from 193nm to 355nm.

Laser Optics

Laser optics are engineered for accurate beam shaping, high-power handling, and minimal wavefront distortion across UV, visible, NIR, and IR wavelengths. Our components support demanding applications in material processing, medical laser systems, telecommunications, and scientific research, delivering consistent performance and long-term reliability.

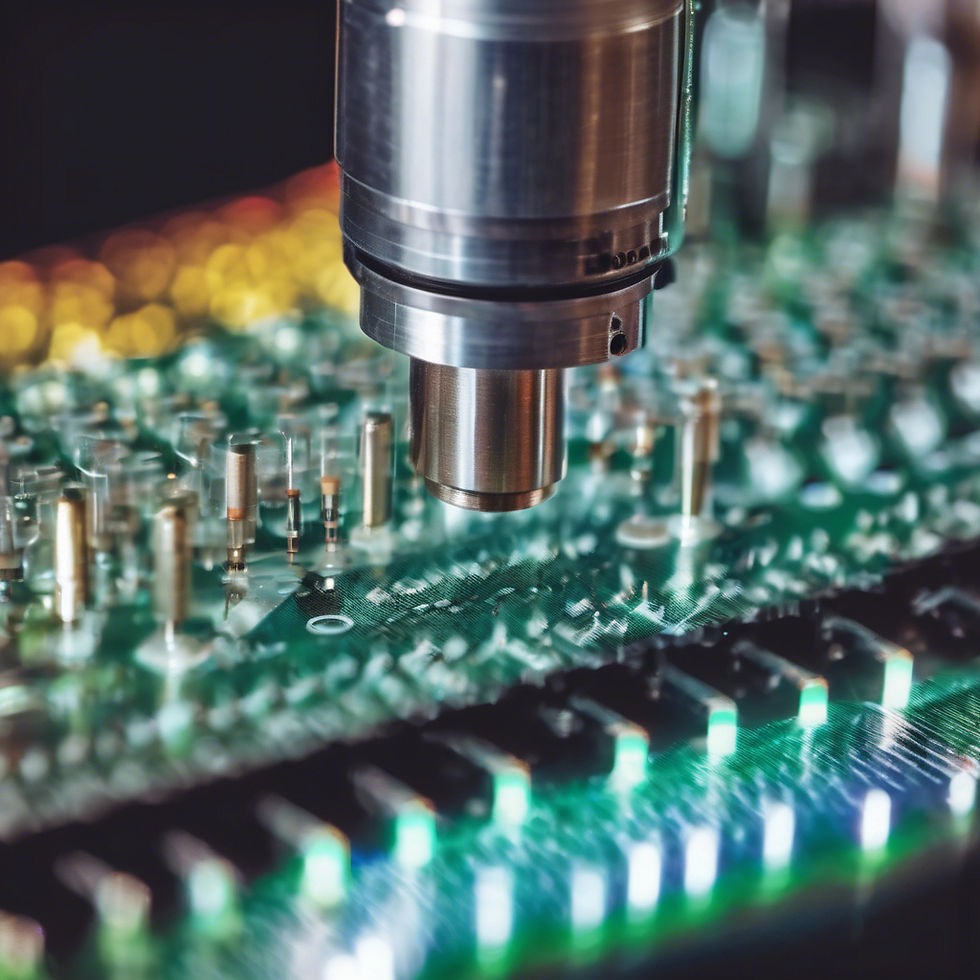

Semiconductor Manufacturing

RMI delivers high-performance optics and coatings for semiconductor manufacturing, inspection, and metrology systems. From deep ultraviolet (DUV) lenses for photolithography to infrared components for thermal analysis, our custom solutions support critical processes across wafer fabrication and defect detection. With advanced thin-film coating capabilities and opto-mechanical integration, RMI enables OEMs to achieve tight tolerances, high damage thresholds, and spectral fidelity across UV, visible, and IR bands—driving innovation in microelectronics and nanofabrication.

Core Capabilities: